Product Development in China

We manage supplier selection, material sourcing, sampling, and production oversight with clear checkpoints and measurable quality controls — across all product categories from electronics to consumer goods.

Best For

Brands, importers, marketplace sellers who need a managed China supply base across multiple product categories.

Delivery Model

Project-based or retainer. Documented decisions, controlled change requests, transparent reporting.

Typical Outcomes

Lower risk, fewer defects, fewer delays, faster decision-making with factories across different industries.

Factories Verified

Sample Approval Rate

Production Runs

Multi-Industry Sourcing Expertise

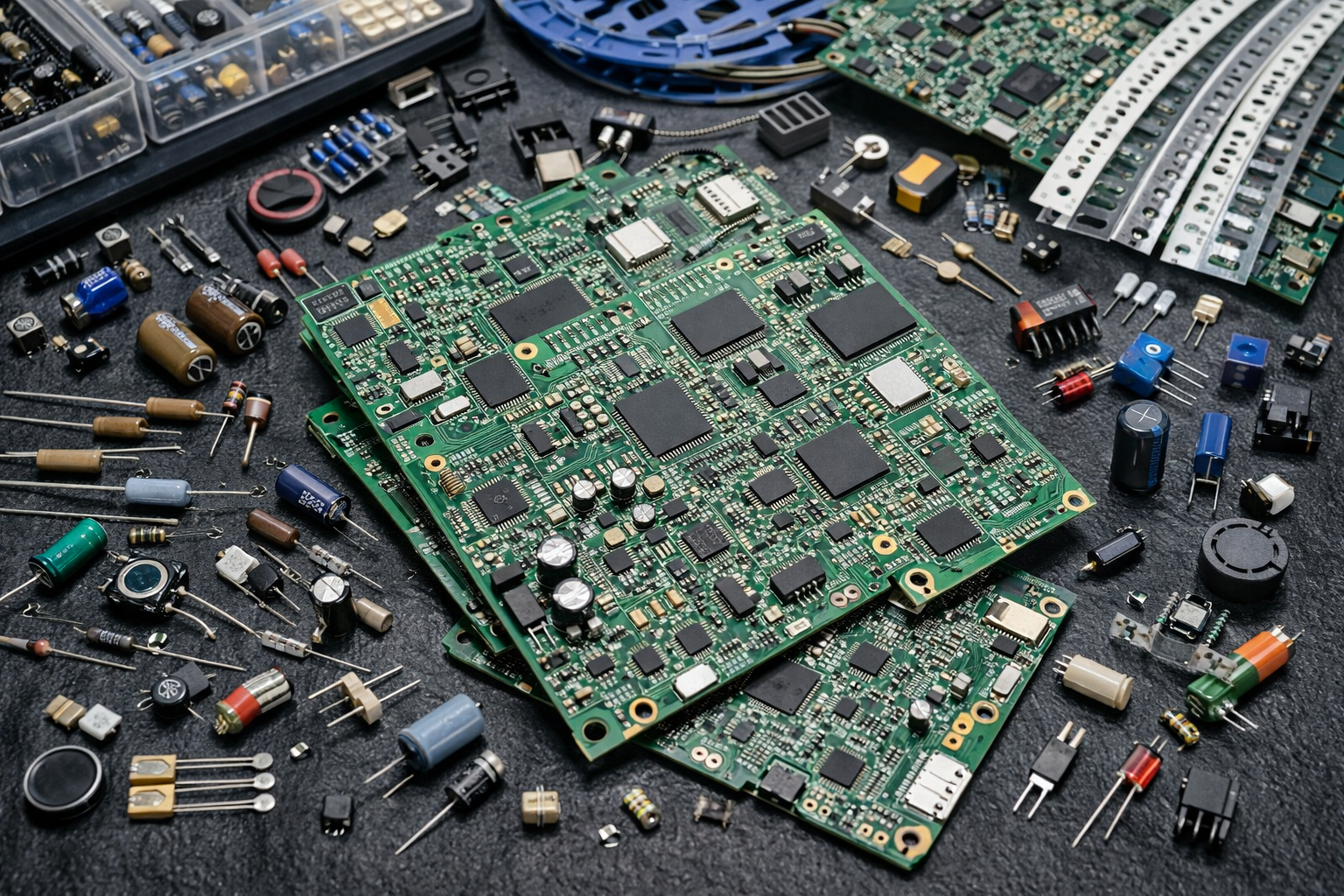

Electronics

Consumer electronics, PCBs, accessories

Home & Garden

Kitchenware, storage, decor

Hardware

Tools, fasteners, metal parts

Consumer Goods

Toys, gifts, lifestyle products

Industrial

Equipment, machinery, components

Packaging

Custom boxes, labels, inserts

Note: For garment and textile manufacturing, visit our dedicated Aurora Fashion platform.

End-to-End Product Development

We bridge the gap between your product requirements and Chinese manufacturing capabilities — ensuring specifications are clear, materials are stable, and quality is controlled from sample to shipment.

This is not broker-style "find me a factory" service. It's structured project management that keeps your product development under control and reduces costly errors at scale — whether you're sourcing electronics, hardware, home goods, or industrial components.

Factory Selection

Verify capabilities, certifications, and capacity across industries.

Material Sourcing

Clear specs, stable suppliers, quality alignment for all components.

Sampling Control

Iterations, approvals, golden sample lock.

Production Oversight

Checkpoints, QC logic, shipping coordination.

Factory Sourcing

We identify, validate, and negotiate with manufacturers that match your product requirements and target economics — across electronics, plastics, metals, and consumer goods. The goal is not "any factory", but a stable production partner you can scale with.

Requirement Definition

We translate your product idea, tech specs, or reference samples into a sourcing brief and acceptance criteria.

- • Product category, materials, construction methods

- • Target price, MOQ, lead time expectations

- • Packaging, labeling, compliance needs (CE, RoHS, FDA)

Shortlist & Due Diligence

We build a shortlist and filter out middlemen, "paper factories", and weak production fits across multiple industries.

- • Capability & specialization verification

- • Export experience and English/Russian communication

- • Risk flags, financial stability, capacity realism

Commercial Negotiation

We compare offers and structure terms that protect quality, timelines, and accountability for your specific product category.

- • Price breakdown & cost optimization levers

- • MOQ scenarios and batch planning strategies

- • Lead time commitments & penalty clauses

Material & Component Sourcing

Materials and components define product quality and cost structure. We source raw materials, semi-finished goods, and finished components across electronics, plastics, metals, and packaging — aligned with your specifications and target economics.

Material Sourcing

Raw materials, semi-finished goods, components from verified suppliers with quality certifications and stable supply chains.

Spec Alignment

Technical specs matched to manufacturing capabilities and quality standards (ISO, CE, RoHS, FDA where applicable).

Pre-Production Validation

Material testing, dimensional checks, and compliance verification before bulk orders to avoid costly mistakes.

Supply Chain Stability

Backup suppliers identified, lead time buffers, and inventory strategies to avoid production delays across all material types.

Electronics & Components

PCBs, semiconductors, connectors, and electronic assemblies

Plastics & Polymers

Injection molding, extrusion, custom compounds

Metal & Hardware

CNC machining, stamping, casting, surface finishing

Packaging Solutions

Custom boxes, labels, inserts, protective packaging

Sampling & Prototyping

Sampling is where quality becomes predictable. We manage iterations, document decisions, and lock an approved "golden sample" before mass production begins — regardless of product category.

Prototype / Initial Sample

Construction validation, spec corrections, manufacturability checks across all materials.

Material Confirmation

Final materials, components, color standards, surface finishing references.

PP Sample

Pre-production sample becomes the benchmark for acceptance and quality control.

Approval & Lock

Approved spec + QC checklist + packaging standard = stable mass production.

Production Management

We run the production plan and checkpoints to keep timelines and quality under control across all manufacturing processes. Change requests are documented and assessed for impact on cost and lead time.

Production Planning

Milestones, material arrival, processing stages, assembly, finishing, and shipment readiness for any product category.

- •Timeline visibility and tracking

- •Capacity constraints mitigation

- •SKU prioritization strategies

Checkpoint Control

We define and track control points to catch issues early and reduce rework across electronics, plastics, metals, and assembly processes.

- •Inline process checks

- •Dimensional accuracy & workmanship

- •Packaging readiness verification

Issue Resolution

We manage defects and delays with corrective actions and documented follow-ups to prevent recurrence.

- •Root-cause analysis

- •Rework coordination and tracking

- •Re-inspection when needed

Supply Chain Coordination

We coordinate factory, materials, components, packaging, and shipment readiness so the handoff to logistics is clean. This reduces delays at the most expensive stage: "ready to ship".

Multi-Supplier Synchronization

When materials, components, and packaging come from different sources, we align delivery windows and priorities across all suppliers.

Shipping Readiness Package

We prepare the information and documents your logistics team needs to move fast: packing lists, quality reports, compliance certificates.

Handoff to Logistics

Structured handoff: what is shipped, how it is packed, what was inspected, what was approved — ready for Aurora Trading logistics services.

Want a Sourcing Plan for Your Product?

Share your product category, target market (EU/RU), approximate volumes, and quality requirements. We'll propose factories, a sampling path, and a production control plan — regardless of whether you're sourcing electronics, consumer goods, or industrial components.