Independent Quality Inspection Services in China

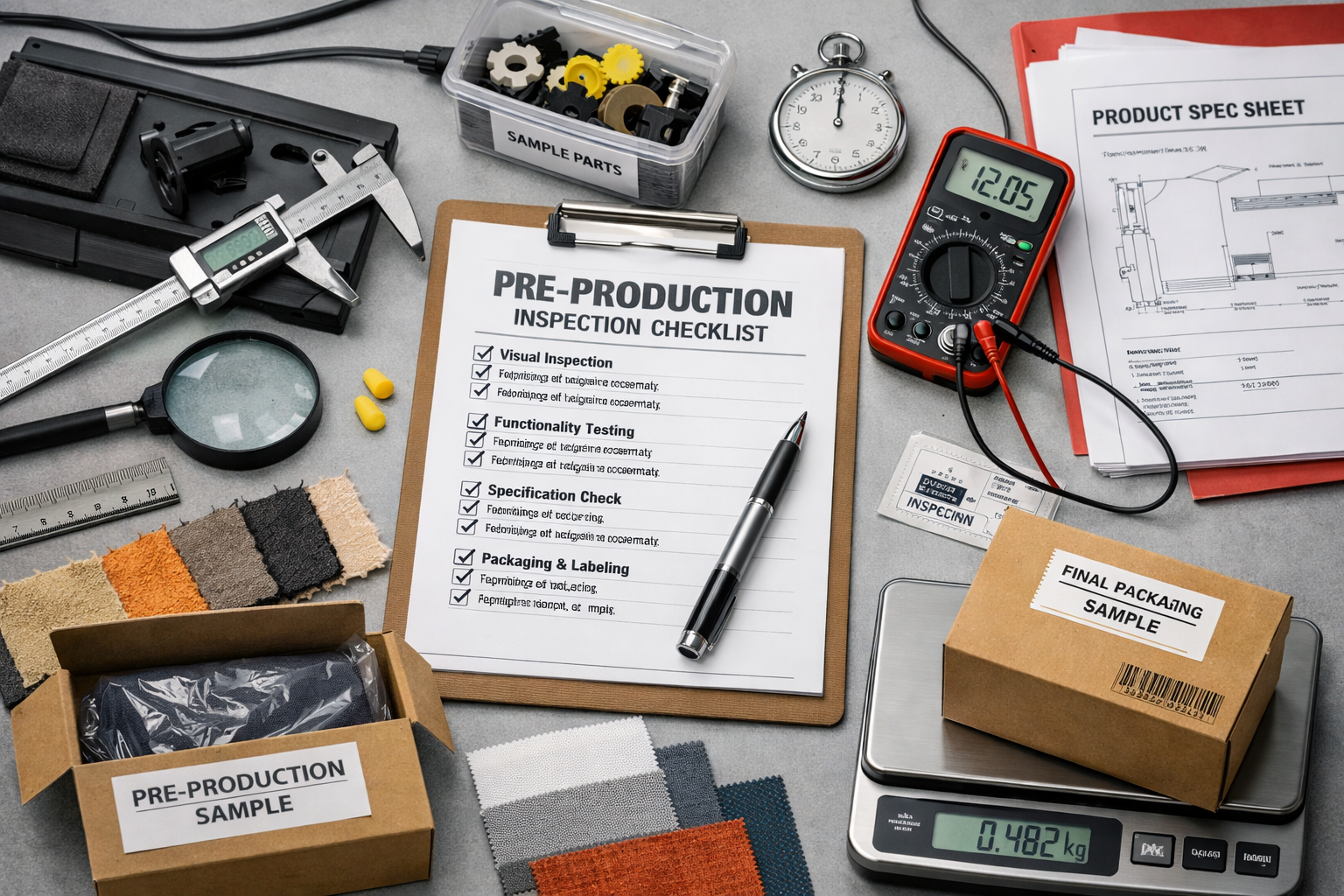

Third-party quality inspections and testing services to verify product compliance, identify defects early, and reduce risk before shipment. We work with accredited labs and experienced inspectors across China's manufacturing regions.

Best For

Importers who need independent verification of product quality before payment or shipment.

Standards

AQL sampling standards, ISO protocols, and client-specific quality requirements.

Reporting

Detailed photo reports, measurements, and pass/fail assessment within 24-48 hours.

Inspections Completed

Report Turnaround

Client Satisfaction

Why Independent Quality Inspection Matters

Factory QC teams have an inherent conflict of interest: they're paid by the factory, not by you. Independent inspection gives you an unbiased assessment of product quality before you commit payment or accept a shipment.

We dispatch experienced inspectors to your factory location. They follow international sampling standards (AQL 2.5 or your custom protocol), document findings with photos and measurements, and deliver a pass/fail report within 24-48 hours.

This creates accountability: factories know their work will be independently verified, which improves compliance with your specifications.

Risk Reduction

Catch defects before shipment. Avoid chargebacks, returns, and reputation damage.

Leverage in Negotiation

Inspection reports give you objective evidence to negotiate repairs or price adjustments.

Data for Improvement

Track defect trends across batches and factories to improve your supply chain.

Four Types of Quality Inspection

Each inspection type serves a different checkpoint in your production timeline. Most clients use a combination: IPC to catch issues early, and PSI to verify final quality.

IPC — Initial Production Check

When: 10-15% of production completed

Verify materials, workmanship, and assembly match approved samples. Catch issues early when corrections are cheapest.

DUPRO — During Production

When: 40-60% of production completed

Monitor production line, check in-process quality, and confirm timelines. Identify problems before they compound.

PSI — Pre-Shipment Inspection

When: 100% finished, 80% packed

Random sampling (AQL standard) of finished goods. Final quality gate before shipment authorization.

CLS — Container Loading Supervision

When: During container loading

Verify quantity, packaging integrity, and proper stowage. Prevent short shipments and damage in transit.

Inspection Standards & Protocols

We follow internationally recognized sampling and acceptance standards, or adapt to your custom quality requirements.

AQL Sampling (ANSI/ASQ Z1.4)

Industry-standard random sampling method. Typical levels: AQL 2.5 (critical), AQL 4.0 (major), AQL 6.5 (minor defects).

ISO 2859 Protocols

Statistical quality control standards for lot-by-lot acceptance inspection.

Custom Checklists

Your specific requirements, measurement tolerances, and acceptance criteria integrated into inspection protocol.

Retail Standards

Target, Walmart, Amazon, and other major retailer quality requirements for packaging, labeling, and compliance.

Fabric & Material Testing

Independent lab testing confirms that materials meet your specifications and target market compliance requirements (EU/US/UK and retailer standards). We work with accredited labs and provide clear, actionable results.

What We Test

Fiber composition, colorfastness, shrinkage, pilling, tensile strength, seam slippage, dimensional stability, and other performance indicators based on product type.

Chemical & Regulatory

REACH / SVHC screening, azo dyes, formaldehyde, heavy metals, phthalates where applicable, and market-specific restrictions for textiles and accessories.

Sampling & Lab Workflow

Sampling can be arranged during inspection (factory pickup) or shipped by the client. We confirm test scope, lead time, and reporting format before submission.

Deliverables

Official lab reports (PDF), pass/fail against stated requirements, and a concise summary highlighting risk items, non-conformities, and recommended corrective actions.

Factory Audit

A factory audit helps you verify supplier capability and reduce onboarding risk before placing large orders. We assess legal status, capacity, quality systems, and ethical/compliance readiness.

Business Verification

Company registration, business scope, ownership indicators, facility existence, and basic operational legitimacy.

Production Capability

Capacity assessment, machinery and key processes, staffing, subcontracting risks, and ability to meet your technical requirements and lead times.

Quality Management

Incoming material control, in-line QC, final QC, calibration, traceability, and how non-conformities are handled (CAPA approach).

Compliance & Social

Basic EHS checks, documentation readiness, and alignment with buyer codes of conduct (where applicable). Findings are summarized with practical recommendations.

Audit Output

You receive a structured report with photo evidence, risk grading, key findings, and a clear recommendation: Proceed / Proceed with Conditions / Not Recommended.

Inspection Process & Timeline

From booking to final report delivery, the typical inspection takes 2-3 days. Rush service available for urgent situations.

Request

You provide: factory address, PO details, inspection requirements

Schedule

We confirm availability and dispatch inspector within 24-48h

On-Site

Inspector performs sampling, measurements, photos (4-8 hours)

Report

Detailed PDF report with photos, measurements, pass/fail

Decision

You use report to approve shipment or request corrections

What's Included in Inspection Reports

Reports are delivered as PDF within 24-48 hours of inspection completion. All findings are documented with photos, measurements, and clear pass/fail assessment.

Product Conformity

Measurements vs. specifications, material verification, construction quality

Defect Classification

Critical, major, and minor defects with photos and descriptions

Packaging & Labeling

Carton quality, marking accuracy, compliance with shipping requirements

Quantity Verification

Carton count, unit count per carton, total quantity reconciliation

Test Results

Functional testing, on-site measurements, performance validation

Recommendation

Pass/Fail/Pending with clear explanation and suggested corrective actions

Ready to Book Your Inspection?

Get independent verification of product quality before you commit payment or accept shipment. Inspection reports delivered within 24-48 hours with detailed photos and pass/fail assessment.