Fashion: From Concept to Bulk

We help brands and e-commerce sellers develop apparel collections in China with clear specifications, reliable materials, accurate samples, and production oversight — aligned with European and Russian market requirements.

What You Get

- ✓ Clear deliverables and checkpoints across development and production

- ✓ Factory-ready documentation to reduce errors, delays, and rework

- ✓ Material options aligned to target quality level and budget

- ✓ Sampling feedback loop + production monitoring until shipment

Collections Developed

First Sample Approval

Minimum Order Quantity

Full-Cycle Apparel Development

Aurora Fashion is your manufacturing partner for building apparel collections in China. We manage tech pack creation, fabric sourcing, sample development, and bulk production — so you can focus on brand, marketing, and sales.

Whether you're launching your first collection or scaling existing styles, we provide structured project management that keeps costs predictable, timelines realistic, and quality under control.

Save up to 40%

Direct factory relationships eliminate middleman markups

30-60 Day Lead Time

Optimized supply chain from fabric to finished goods

Certified Factories

WRAP, GOTS, Sedex partners with proven export records

3-Stage QC

Pre-production, in-line, final inspections included

Design & Development

We transform your design concepts into factory-ready technical documentation. This phase establishes clear specifications that reduce sampling rounds and prevent production errors.

Tech Pack Creation

Detailed technical drawings, measurements, construction notes, and material specifications.

- •Flat sketches (front/back/details)

- •Point of measure (POM) charts

- •Construction details & seams

- •Bill of materials (BOM)

Design Support

We help refine designs for manufacturability and cost efficiency without losing aesthetic intent.

- •Construction feasibility review

- •Cost optimization suggestions

- •Material substitution options

- •Fit & grading recommendations

Why It Matters

A strong tech pack reduces sampling rounds, protects the fit, and makes supplier quotes comparable.

Tech Pack Creation

Professional technical specifications that eliminate miscommunication between design and production. A comprehensive tech pack is your production insurance policy.

Complete Package Includes

- ✓Flat technical sketches (front, back, side, detail views)

- ✓Point of Measure (POM) with tolerance ranges

- ✓Construction details & seam specifications

- ✓Complete Bill of Materials (BOM)

- ✓Color callouts & Pantone references

- ✓Grading rules & size specifications

- ✓Care labels & packaging requirements

Why Professional Tech Packs Matter

Tech packs reduce sampling rounds by 40%, prevent fit issues, and make factory quotes directly comparable. They serve as the single source of truth for production teams.

📦 What You Receive

Complete tech pack package in PDF format with all specifications, measurements, and material details. Factory-ready documentation that ensures accurate quotes and production.

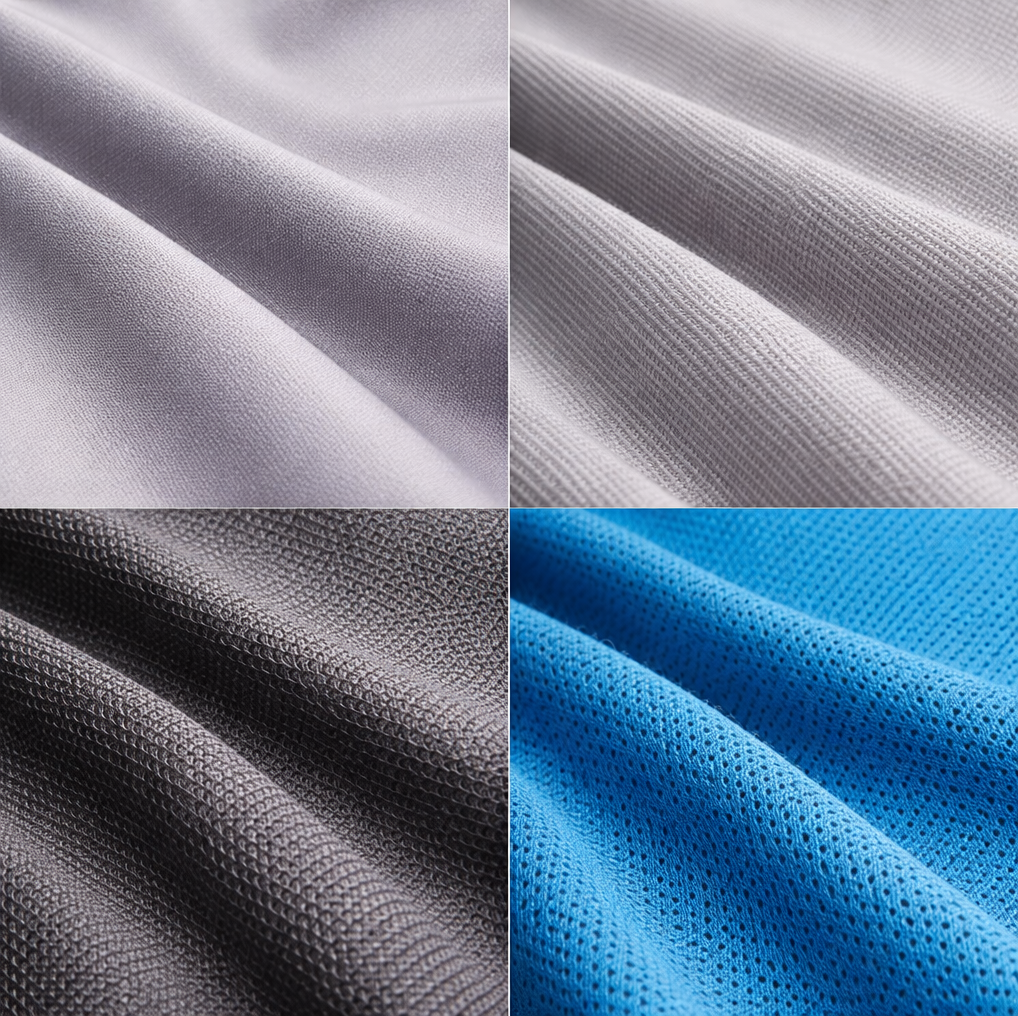

Fabric & Trim Sourcing

We source materials that match your target handfeel, durability, and compliance expectations — with transparent options and trade-offs, not guesswork.

Access to major textile hubs in Shanghai, Guangzhou (Guangdong), Zhejiang, and Jiangsu — allowing us to find specialized fabrics at competitive mill prices.

Selection Criteria

- ✓ Handfeel & drape aligned with silhouette and season

- ✓ Performance: shrinkage, colorfastness, pilling, recovery

- ✓ Supply stability: lead times, minimums, color continuity

- ✓ Budget fit: smart substitutions without visible quality loss

What You Receive

- 📦Shortlisted fabric & trim options with pros/cons

- 🎨Swatch set and labeling for internal approvals

- 📋Material specs aligned to tech pack BOM

💡 If you sell online, we can prioritize "camera-friendly" materials: reduced shine, stable color, predictable texture.

Material Types We Source

Sample Making

Sampling is where issues surface early — fit, construction, and finishing. We manage iterations and create a clean approval record so bulk production repeats the approved standard.

Sampling Process

- 1 Pre-sample briefing — Align factory on critical points and expectations

- 2 Fit review — Measurement check with tolerance logic and adjustment notes

- 3 Construction review — Seams, stress areas, symmetry, finishing details

- 4 Iteration tracking — Comments, photos, revision control documentation

- 5 Material confirmation — Final fabric, trims, color standards locked

⏱️ Timeline: First sample typically ready in 7-10 days. Allow 2-3 iterations for fit refinement.

Approval Gate

We lock the "golden sample" and align it to tech pack + BOM so the bulk line matches the approved reference.

Deliverables:

- ✓ Golden sample confirmation + critical-to-quality list

- ✓ Updated tech pack for bulk production with all revisions

- ✓ Risk list and preventive controls for production phase

First-Time Sample Approval Rate

Bulk Production

Production is managed against measurable checkpoints: material readiness, line setup, in-process control, and final conformance to the approved sample.

Production Control

- 🎯 Kick-off alignment: Golden sample, tolerances, packing standard review

- 👁️ In-line monitoring: Workmanship, critical seams, measurement spot-checks

- ✨ Finishing review: Pressing, threads, stains, labeling accuracy

- 📦 Pre-shipment readiness: Carton marking, polybags, assortments verified

Expected Outcomes

Stable Repeatability

Fewer Claims

On-Time Shipping

💡 Optional: Connect this workflow with Quality Control services (PPI / DUPRO / FRI) to formalize inspections per batch.

Typical Production Timeline

Material arrival & cutting room setup

Cutting & pattern verification

Sewing production (inline QC at 30%)

Finishing, pressing, quality checks

Packing, labeling, final inspection (FRI)

Ready to ship 🚀

Minimum Order Quantity (MOQ)

Standard MOQ starts at 300 units per style for most garment categories. Can be adjusted based on complexity and fabric availability.

Ready to Develop Your Collection?

Share your product category, target market (EU/RU), estimated volumes, and design references. We'll prepare a project plan with timelines, factory options, and cost estimates.